Our Clients

Why Us

TRUSTED NAME

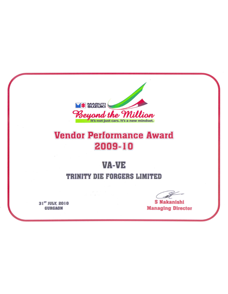

Trinity India is a Trusted name in Forged & Machined Auto Components. We are influenced by nothing but our clients’ interest and hence we have a list of very high profile happy clients from diverse industries. We have served leading companies across globe especially in automotive industry along with Pump and Valve, Hydraulic and Material Handling industries.

MODERN MACHINERY

Trinity India is equipped with modern machinery for achieving best quality products. With the use of latest technologies for engineering and design along with fully equipped laboratories, Trinity India also possesses modern forging presses and hammers to produce high quality forgings along with world class facilities for heat treatment, CNC,Broaching, VMC, Induction hardening,etc.

EMPHASIS ON QUALITY

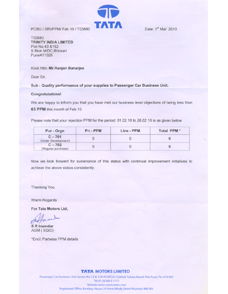

Trinity India emphasises on quality to the extent of regularly delighting its customers. A strong culture of continuous improvement, a systematic approach to quality assurance and a team of skilled and dedicated manpower ensures high quality timely deliveries.

LEADING MANUFACTURERS

Trinity India is one of the leading manufacturers of ready to assemble forgings and machined components. Our products are made as per client's requirement using Carbon Steel, Alloy Steel & Stainless Steel. We have major exports of forged and machine components to United States of America, United Kingdom, Germany, Spain, Sweden, Finland, Ireland, Czech Republic and many others.

Products

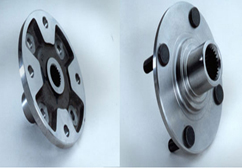

Front Wheel Hubs

Steering Levers

Propeller Shaft Components

Yokes

Rear Wheel Spindles

Powertrain Parts

Material Handling Industry

Radial Piston Motor Cylinder Blocks

Stub Axles

Differential Parts

Pump and Valve Industry

Gear Blanks

Fractured Connecting Rods

Camshafts

Hydraulic Industry

Universal Joint Parts

LOOKING FOR ADEQUATE SOLUTION FOR YOUR COMPANY?

REQUEST A QUOTEIndustries

Automotive Industry

Material Handling

Railway

Pump and Valve

Construction

Power Generation

Hydraulic Handling

Marine

Industrial Goods

From Idea To Realization

Recognizing the need is the primary condition for design. We have a team of well skilled managers and engineers who understand the client’s requirement and analyze the tech feasibility of the product requirement.

We have advanced high-end software and technology installed for designing, analyzing and simulating the product design as per client’s needs.

Our Designing and Simulation facilities comprises of:

• Uni Graphics NX6 CAD Software

• Uni Graphics CAM Software

• Deform Simulation Software

• Forge 11 for virtual manufacturing on special request of clients

“Without a strong foundation, you cannot create anything of value” Trinity India strongly believes in this, and hence we have dedicated experts to plan the entire product flow inline with client’s needs.

Trinity India values the ever-growing technology and process, which ensures that our manufacturing facilities and technical know-how consistently remains at the cutting edge and world class level.

Quality of a finished product largely depends on what material is used to make the product. Trinity India performs an extensive analysis in terms of selecting appropriate raw material for making products with defined specifications.

Trinity India uses highly rated Carbon Steel, Alloy Steel & Stainless Steel as raw materials depending on clients’ requirements.

Taking quality of raw material as the first priority we have well equipped lab with raw material testing facility.

“To make the best you need the best” we believe that no company can deliver the best without having the infrastructure and resources to do it, and hence we have invested heavily in latest technology & modern machinery to become a fully automated production plant.

Trinity India has a par excellence infrastructure and facility, which is used to manufacture products that are being used by many companies across globe.

“Total quality management is a journey, not a destination.” And at Trinity India we perform quality check at every step of our production cycle, right from the First Piece whose Inspection report includes process parameters and IMTE.

We possess equipment for critical dimension measurement and also have in-house calibration facility.

We perform a Final inspection of the batch before dispatch since we strive to attain acceptance level of 100% every time we deliver.

Having achieved the final product, Trinity India does not just stop at that, we prepare the perfect packaging parcel for the batch of products and accurate documentation with detailed specification for every product.

Trinity India has a very good record for timely deliverables with the highest-level quality of products.

“The product is only called a finished product when the client is delighted to have it” and Trinity India has a very huge base of delighted clients in varied industries and across globe who TRUST us providing them with products par excellence.

What Others Say

Advent Developers Pvt. Ltd.

Advent Developers Pvt. Ltd.