Introduction

Forge Trinity is a reliable CNC Machined Parts and Components Manufacturer & Supplier for various applications. We offer precise & complex CNC machining solutions. CNC machining is a process of creating custom-designed parts by using computer-controlled machines that follow a set of instructions to cut and shape steel. CNC machines can perform various operations such as drilling, milling, turning, boring, tapping, etc. CNC machining can produce parts with high accuracy, consistency, and surface finish.

Types of CNC Machines and Materials

There are different types of CNC machines that can be used for making parts, such as:

- CNC milling machines: These machines use rotary cutting tools to remove material from a workpiece that is fixed on a table. The cutting tools can move along multiple axes to create different shapes and features on the part. CNC milling machines can produce parts with complex geometries and fine details.

- CNC turning machines: These machines use a single-point cutting tool to remove material from a rotating workpiece that is held on a spindle. The cutting tool can move along one or two axes to create cylindrical or conical shapes on the part. CNC turning machines can produce parts with high precision and surface finish.

- CNC router machines: These machines use spinning cutting tools to cut and carve material from a flat workpiece that is fixed on a table. The cutting tools can move along three or more axes to create 2D or 3D shapes on the part. CNC router machines can produce parts with intricate patterns and designs.

- CNC laser machines: These machines use a focused beam of light to cut or engrave material from a workpiece that is fixed on a table. The laser beam can move along two or more axes to create precise and smooth cuts on the part. CNC laser machines can produce parts with high accuracy and quality.

The most common materials used for CNC machining are metal alloys, such as carbon steel, alloy steel, etc. Metal alloys have high strength, durability, conductivity, and resistance to corrosion and wear.

Benefits of CNC Machined Parts

CNC machining has many benefits for making parts, such as:

- High precision: CNC machining can produce parts with tight tolerances and fine features that are difficult or impossible to achieve by manual machining.

- High efficiency: CNC machining can reduce the production time and cost by automating the machining process and eliminating the need for human intervention and errors.

- High flexibility: CNC machining can produce parts with various shapes and sizes by changing the program and tooling according to the design requirements.

- High quality: CNC machining can ensure consistent quality and performance of the parts by minimizing the defects and variations in the machining process.

Products

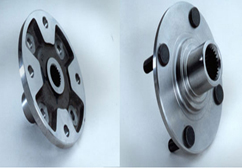

Front Wheel Hubs

Steering Levers

Propeller Shaft Components

Yokes

Rear Wheel Spindles

Powertrain Parts

Material Handling Industry

Radial Piston Motor Cylinder Blocks

Stub Axles

Differential Parts

Pump and Valve Industry

Gear Blanks

Fractured Connecting Rods

Camshafts

Hydraulic Industry

Advent Developers Pvt. Ltd.

Advent Developers Pvt. Ltd.