Forging in Railway Industry

Forging plays a crucial role in the railway industry by enabling the production of durable and precise components that withstand high stress and demanding operational conditions. It is used to create essential parts for locomotives, railcars, and other railway equipment, ensuring safe and efficient train operations. Indian forging companies are contributing significantly to the growth and modernization of the railway sector.

Common Materials Used

We utilize high-quality materials to ensure superior performance and longevity:

Steel

Renowned for its strength and versatility, ideal for railway applications.

Specialized Alloys

Tailored solutions for specific railway needs, offering enhanced durability and functionality.

Railway Components We Manufacture

At Forge Trinity India, we specialize in the production of high-quality forged components for the railway industry, including:

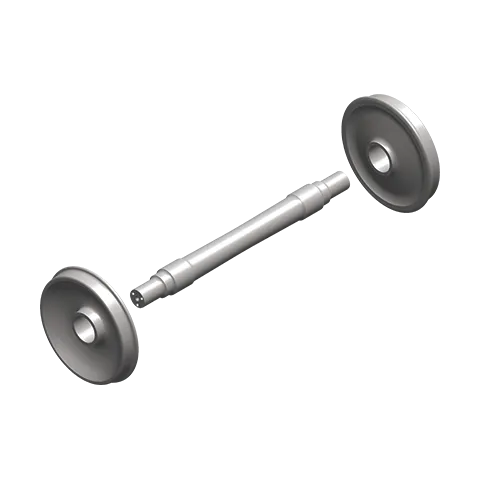

Wheels

Forged wheels designed to withstand high speeds, extreme loads, and powerful accelerations in railway operations.

Axles

Durable and robust axles forged to provide strength and reliability for train support.

Engine Components

Critical parts like crankshafts, connecting rods, and pistons for efficient and dependable locomotive engines.

Bogie Components

Strong and reliable forged components for bogies that support train wheels and axles.

Railway Electrification

Forged connectors and insulators to ensure reliable power transmission in railway electrification infrastructure.

Coupling, Braking, and Suspension Systems

Safety-critical components forged to ensure smooth and safe train operations.

Our Manufacturing Process

We pride ourselves on a streamlined, high-quality forging process:

Customer Collaboration

Drawings and requirements received from the client.

Engineering Precision

Cost evaluation, die design, and process planning.

Material Excellence

Sourcing and checking billets in our lab.

Forging

Shaping raw materials with precision equipment.

Delivery

On-time delivery of precision-engineered components.

Heat Treatment & Shot

checkpoints for hardness, MPN, and final inspections.

Quality Control

Multiple materials with precision equipment.

Blasting

Enhancing strength and surface quality.

Why Choose Forge Trinity India?

Expertise

Decades of experience in industrial forging.

Quality Assurance

Rigorous quality checks at every stage.

Innovation

Cutting-edge technology for unmatched precision.

Customer-Centric Approach

Tailored solutions to meet your unique needs.

FAQs Section

01. What makes forged components better than cast ones?

Forging produces stronger and more durable parts, ideal for high-performance applications.

02. Can you customize components for unique requirements?

Absolutely! Our engineering team collaborates with clients to deliver tailor-made solutions.

Advent Developers Pvt. Ltd.

Advent Developers Pvt. Ltd.